Quality Assurance

Home > Electronics Development > R&D processes > Quality Assurance

Quality Level

The development processes at Melecs are based on the V model, inspired by ASPICE. We distinguish between three different quality levels: product quality, quality of the work results and process quality.

Process quality

Quality of the

work results

Product quality

PROCESS QUALITY

The development processes at Melecs are based on the V model, inspired by ASPICE.

ASPICE is the German acronym for Automotive Software Process Improvement and Capability Determination. It is a quality standard used to assess the performance of development processes.

It forms the basis for the standardized work in our product developments.

The Melecs process landscape describes the development processes at the task level, which are tailored to the dimensions of the project.

The development of complex products requires the interaction of many areas. The interfaces are governed in the process landscape through defined inputs and outputs.

To safeguard the high quality of our products, the observance of these processes is regularly monitored and constantly updated. The management also monitors the maturity of our projects at defined milestones. The next project phase is only initiated following a positive assessment of the milestone review.

QUALITY OF THE WORK RESULTS

Every sub-process in development has defined work results, such as product sketches, layout and schematics documentation.

The availability and defined quality of the work results is a precondition for on-schedule realization of the product development.

To ensure the quality of the work results, and to guarantee the scheduled progress of the project, reviews, simulations or other tools are applied. Their proper execution is in turn monitored by the Quality department.

PRODUCT QUALITY

The product quality is tested throughout the development process with the aid of multi-level tests and is finally approved after product validation.

A multi-level test strategy is developed specifically for every product that we develop. To be able to identify potential deviations as early as possible, the complexity and the duration of the tests increase from the base to the tip of the test tree. This allows causes to be identified and corrective measures to be taken. This aims to ensure that tight schedules can be upheld.

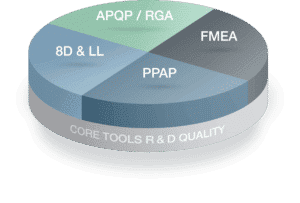

Quality Assurance - Core Tools

We execute our projects based on a maturity model that is combined with the V model.

We do preventive failure avoidance based on failure modes and effects analysis. These are developed in multi-disciplinary teams for our product concepts. Defined interfaces are used to transmit the information from the design to the process FMEA and to ensure the consistency of the specific features.

The First Article Inspection documentation and approval is generally based on results from product and process development. The contents are coordinated with our customers for the specific project and transmitted during the approval process.

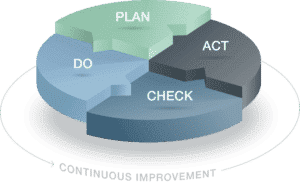

PDCA – Plan Do Check Act

One of the central tools of quality assurance is the PDCA cycle, which is used in all areas of our company. The improvement measures are centrally administered via the Melecs tool CALM – Central Action List Melecs. This enables, for example, measures from Lessons Learned audits, internal improvements etc. to be processed in a structured way, followed up automatically and centrally documented.

Should deviations or problems arise during the course of the development, these are processed in a structured manner. At Melecs, we use different methods depending on the problem; these can be combined. To ensure structured work on solutions to the problems, we use, amongst others, the 8D System, frequently in combination with Ishikawa diagrams and 5-Why analyses to identify the root causes. To prevent the error from being repeated, systemic measures are implemented during the Lessons Learned process, based on the root cause.

Safety Management

Safety Management Safety Management that is independent from the development ensures that normative requirements and the state of the art in science and technology are taken into account at the start of development.

We will be happy to personally advise you.

Would you like to learn more about our service portfolio or do you have a specific request? Our experts will be happy to help you.