Hardware Engineering

Home > Electronics Development > R&D processes > Hardware Engineering

Hardware Development

The hardware development process at Melecs is closely linked with the services of our components experts in Purchasing, Software and Production. This ensures that the requirements of the components – with regard to price, availability, durability and manufacturability – are optimally satisfied.

Thanks to our R&D experts’ experience, EMC is already considered in the design process. Measurements during development, performed at our own test centres, prevent expensive development loops.

A wide variety of simulation options support mature development as a solid basis for your product’s success.

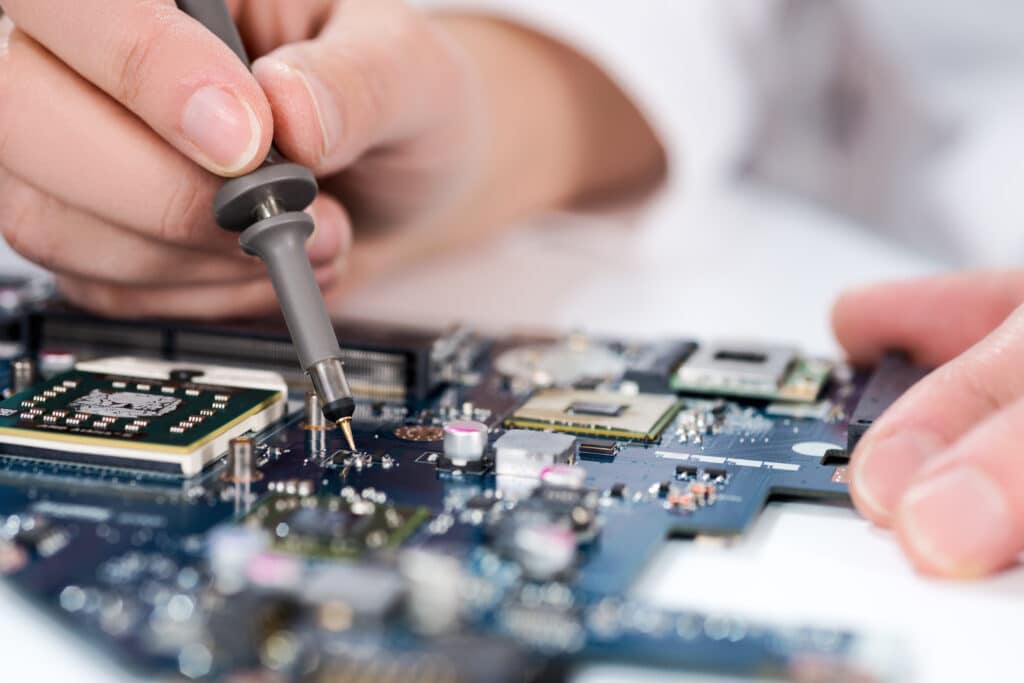

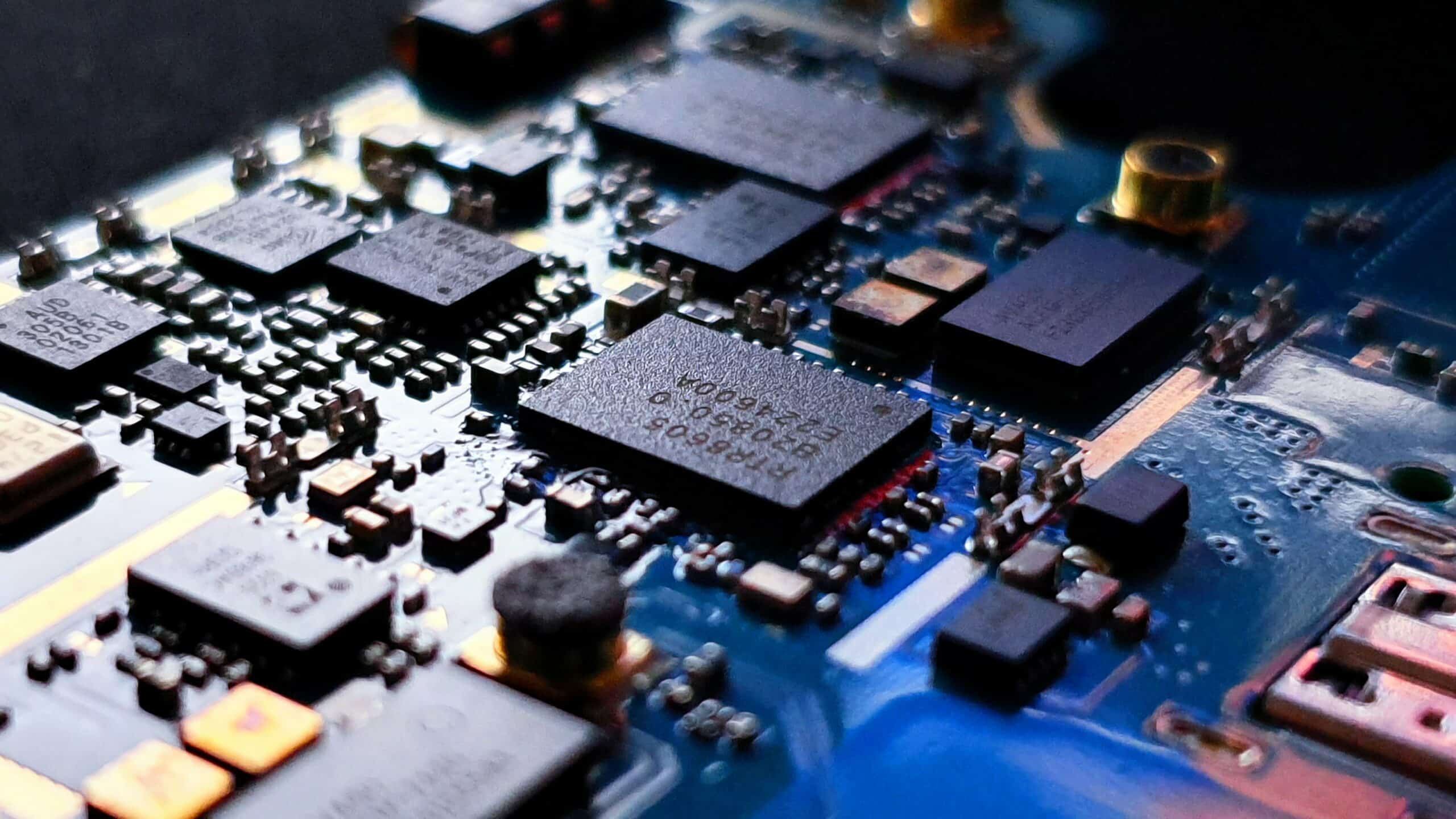

PCBA DEVELOPMENT

A circuit board layout developed by our experts is an essential component for successful electronics development. Melecs PCBA development includes the following aspects:

- PCBA Design of multilayer boards, hard and flexible boards

- Digital interfaces to mechanical constructions: *.dxf, *.step, *.pdf

- DfT – Design for Testing according to Melecs’ internal design guidelines

- DfM – Design for Manufacturing

- Impedance-controlled signal transmission

- EMC-conform layout

- High Speed Routing up to 2 GHz

- Global network of circuit board manufacturers

- PCBA Design of multilayer boards, hard and flexible boards

- Digital interfaces to mechanical constructions: *.dxf, *.step, *.pdf

- DfT – Design for Testing according to Melecs’ internal design guidelines

- DfM – Design for Manufacturing

- Impedance-controlled signal transmission

- EMC-conform layout

- High Speed Routing up to 2 GHz

- Global network of circuit board manufacturers

DESIGN

In the design phase, we develop your tailored hardware concept. In close collaboration with you, we collect and define your requirements, which are first specified in a requirements management tool and then precisely adhered to.

This guarantees a maximum of transparency and a defined mechanism for status checks along the entire process, beginning with the definition and extending to implementation and testing. The hardware architecture is created based on the requirements and is represented in a function block diagram that visualizes all major functionalities.

DEVELOPMENT

In the development phase, the hardware function groups are defined in more detail and integrated into a circuit diagram. A PCBA layout is then developed based on this circuit diagram.

A detailed schematic draft is created according to the architectural function blocks. A detailed analysis, including a worst-case study, tolerances and ageing, ensures that the draft is reliable and will run for the product’s entire lifetime.

Electrical simulations are key to the creation of reliable designs and to the static and dynamic analysis of the design.

Thermal feasibility studies are the basis for modern designs to ensure stable function over a wide temperature range.

The PCBA layout is a significant element of successful product development. We take key factors, such as signal integrity and EMC behaviour, into account early in the development stage, thus ensuring a high degree of product maturity.

The 3D collision testing enables product development hand-in-hand with the mechanical construction department.

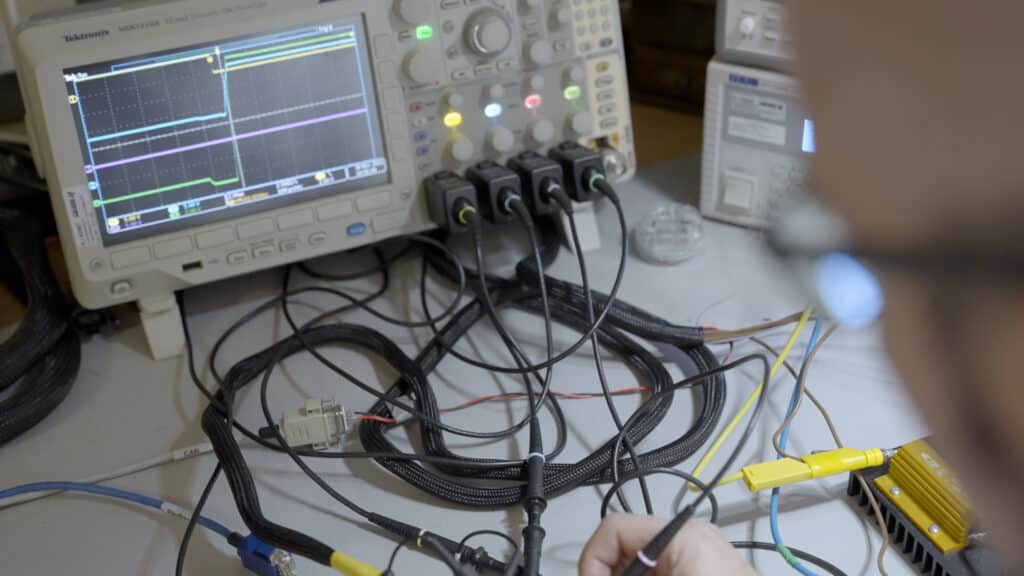

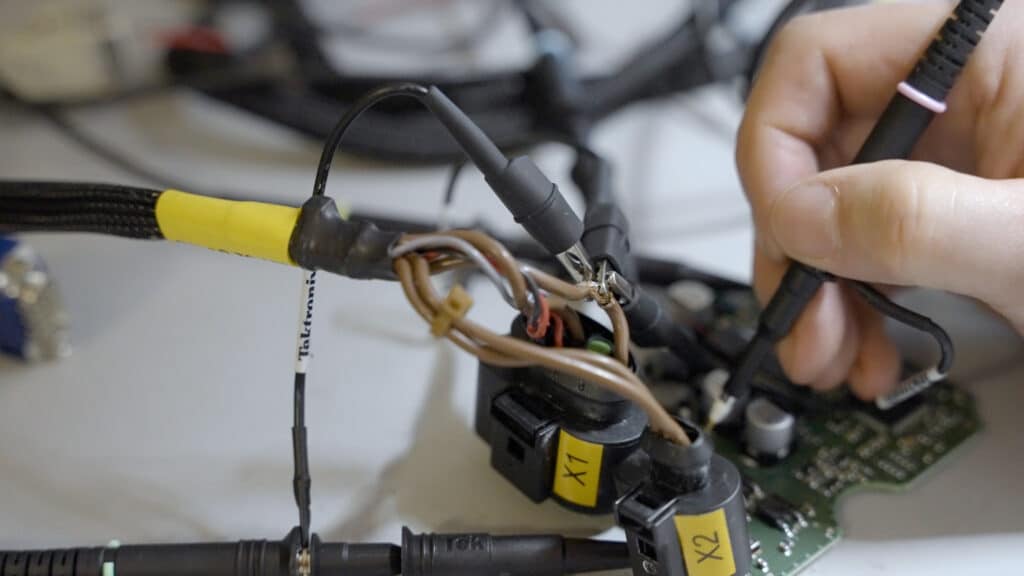

TEST

The test specification is drawn up to ensure that the design fulfils all specified requirements and corresponds exactly to the customer’s instructions.

The hardware test then ensures the full functionality of the draft.

The in-house development of a graphical user interface (GUI) ensures the presence of the necessary interface to carry out the complete range of tests.

Our hardware experts accompany the product from initial concept to product validation, ensuring a seamless and time-saving development cycle

Application examples:

- Automotive Lighting

- Automotive ECU

- Automotive 48 V

- Industrial Applications

- Home Appliances

- Automotive Lighting

- Automotive ECU

- Automotive 48 V

- Industrial Applications

- Home Appliances

Software Engineering

Melecs develops high-performance software for our core sectors: Automotive, Home Appliances and Industrial.

We will be happy to personally advise you.

Would you like to learn more about our service portfolio or do you have a specific request? Our experts will be happy to help you.